Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Model No.: SJW

Brand: XINDA

Processing Plastic Type: Hdpe, Hdpe/Pp, Pa, Pe/Pp, Lldpe, Polystyrene, Abs/Pp, Evoh, Wood-Plastic, Ppr, Pp, Frpp/Pvc, Pvc, Mlldpe, Ldpe, Abs, Pet, Eva, Pc, Polylactic Acid, Eps

Status: New

Video Factory Inspection: Provided

Mechanical Test Report: Provided

Marketing Type: Ordinary Product

Core Component Warranty Period: 1 Year

Core Components: Plc, Engine, Bearing, Gearbox, Motor, Pressure Vessel, Gear, Pump

Place Of Origin: China

Machine Type: Granulating Production Line

Screw Design: Single

Warranty Period: 1 Year

Out-of-warranty Service: Video Technical Support, Online Support, Spare Parts, Field Maintenance And Repair Service

Where To Provide Local Services (in Which Countries Are There Overseas Service Outlets): Egypt, Canada, Turkey, Italy, Viet Nam, Indonesia, Thailand

Showroom Location (in Which Countries Are There Sample Rooms Overseas): Canada, Turkey, Italy, Viet Nam, Russia, Thailand

Raw Material: PP

Screw: Single-Screw

Inverter: Inverter

Electromagnetic Heater: Electromagnetic Heater

Automation: Automatic

Computerized: Computerized

Customized: Customized

Certification: SGS

Condition: New

Motor: Siemens Brand

Key Selling Points: Automatic

Output (kg/h):: 5-1800kg/h

Screw Type: Double Screw

Processing Type: Compouding/extruder/pelletizing

Used For: Pelletizing Granules

Voltage: 220V~340V

Motor Power: 200-250kw

Screw&barrel: Co-rotating,double Screw,clamshell

Application:: Color Masterbatch,Hot-melt Adhesive,ect

Packaging: Wood Box and Pallet

Productivity: 5-1800KG/H

Transportation: Ocean,Land,Air

Place of Origin: Jiangsu,China

Supply Ability: 1000

Certificate: ISO9001,CE,SGS

HS Code: 84772010

Port: SHANGHAI,QINGDAO,NINGBO

Payment Type: L/C,T/T,D/P,Paypal,Money Gram,Western Union

Incoterm: FOB,CFR,CIF,EXW,FCA,CPT,CIP

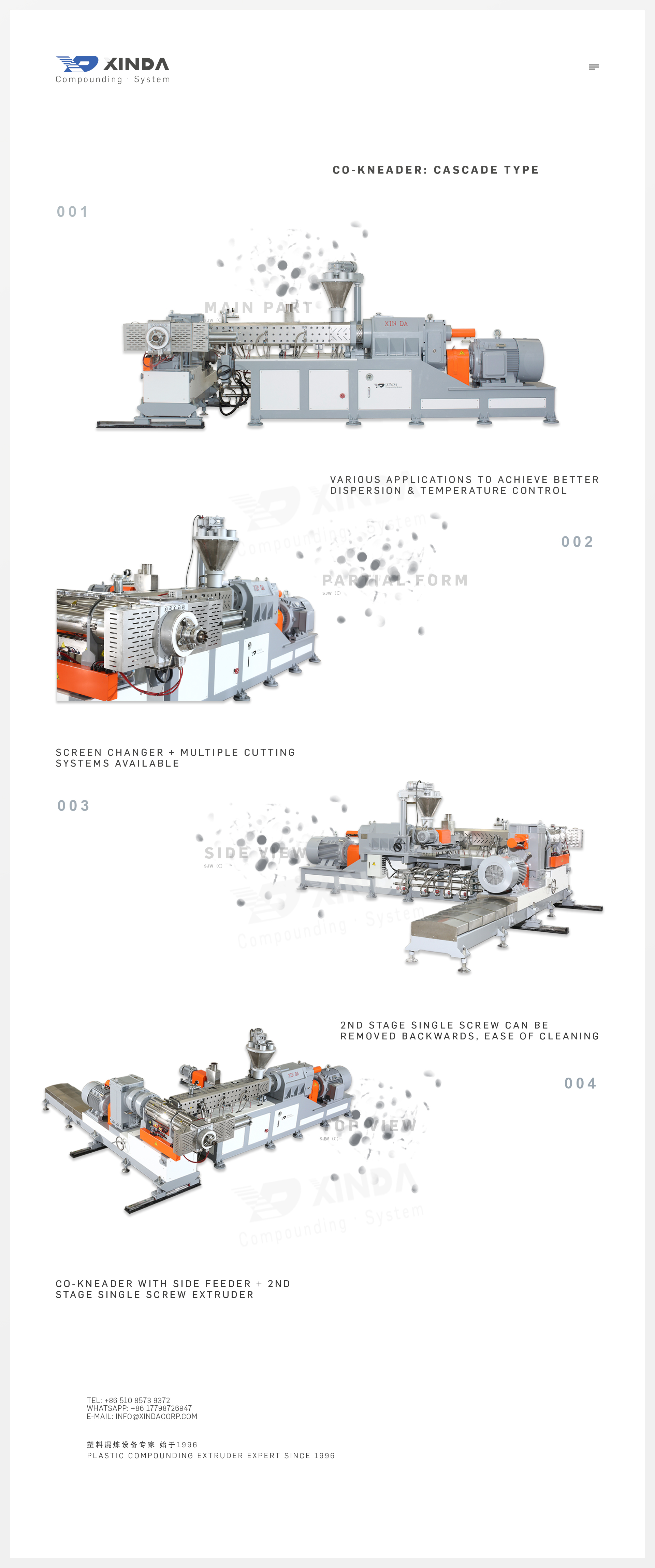

Shading Compounds Kneading Compounding Extruder Line

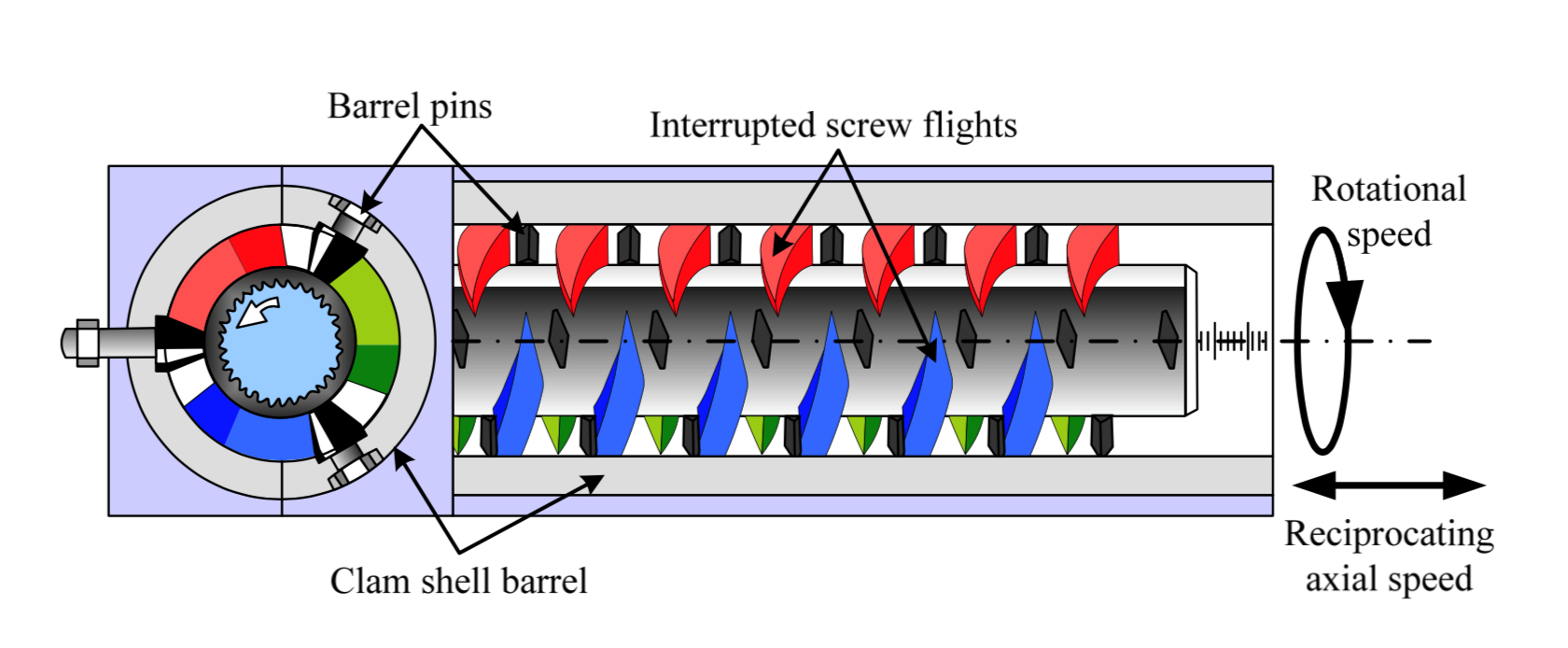

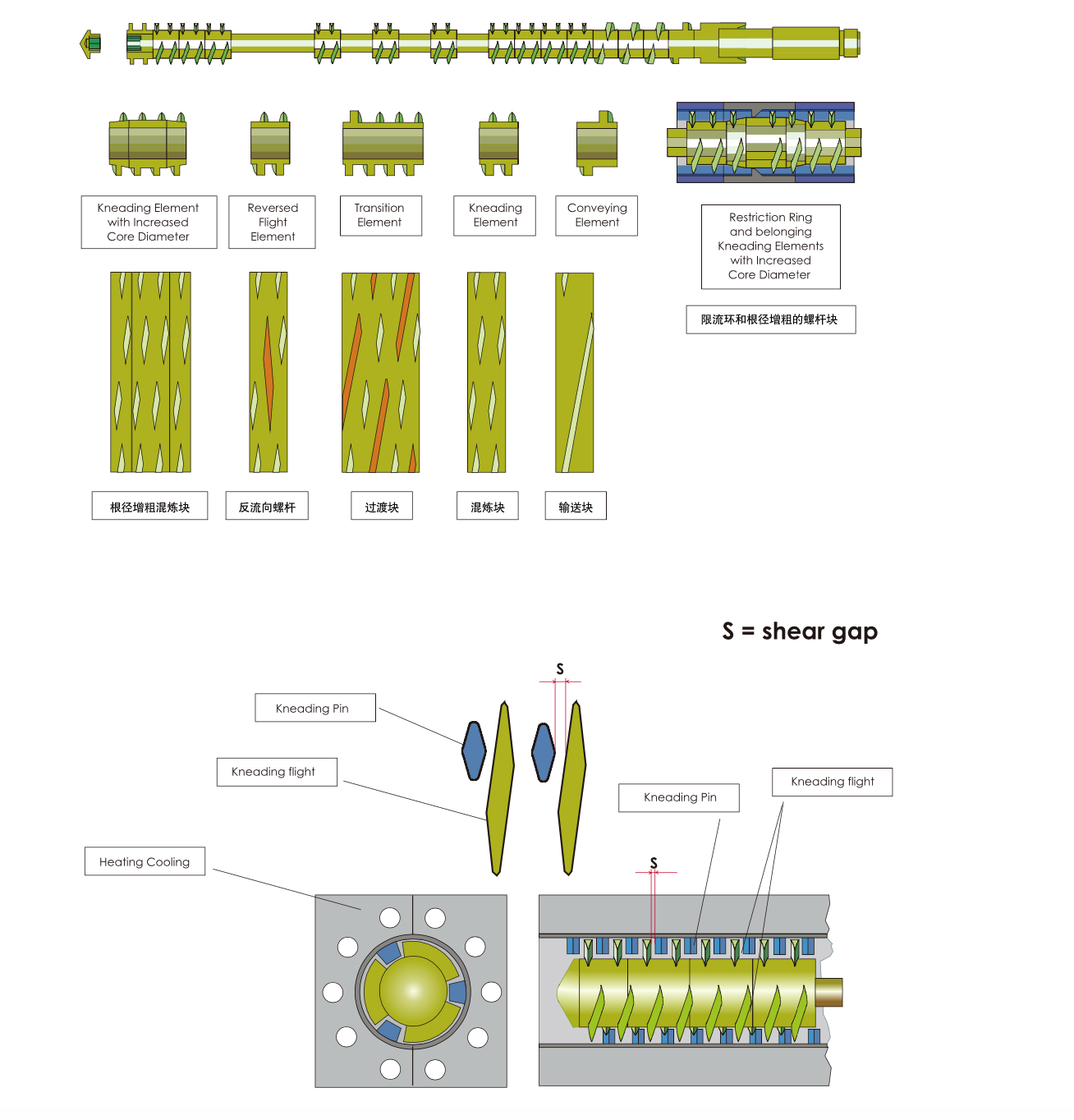

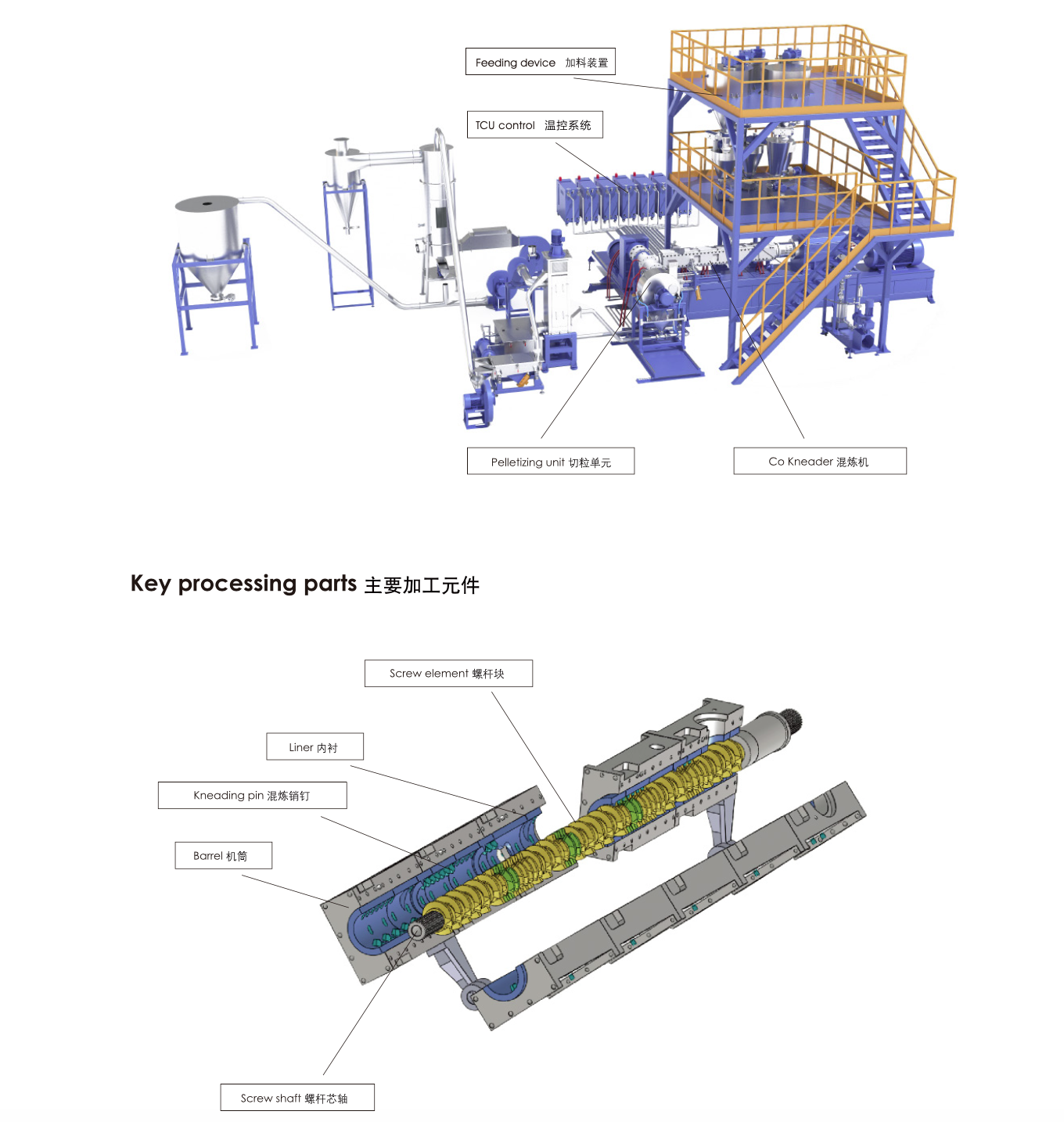

The Shading Compounds Kneading Compounding Extruder Line of Co-kneader reciprocating kneader consists essentially of the following assemblies:gearbox,oscillating equipment,vertical feeder,side feeder,screw,barrel,temperature control system,lubricant system.

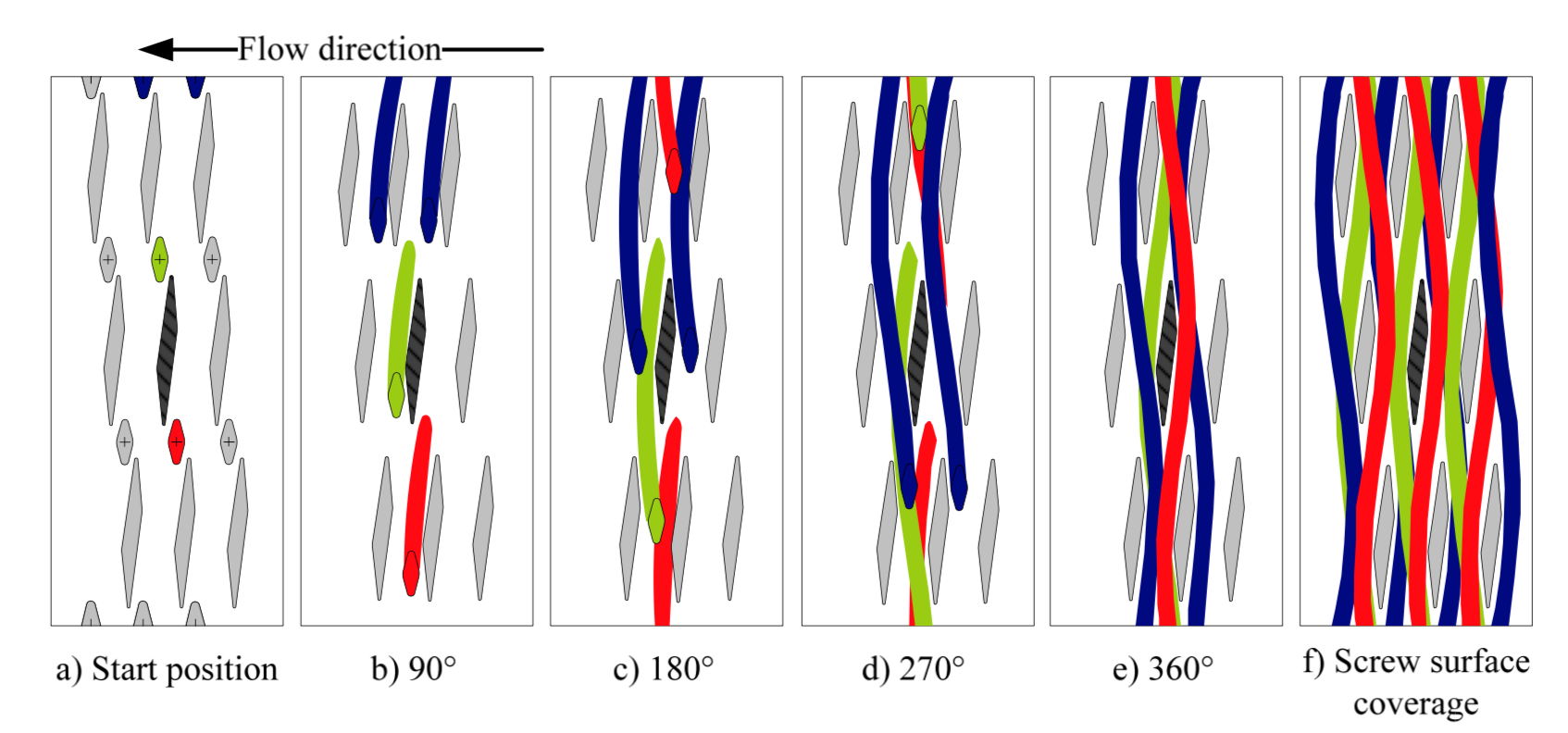

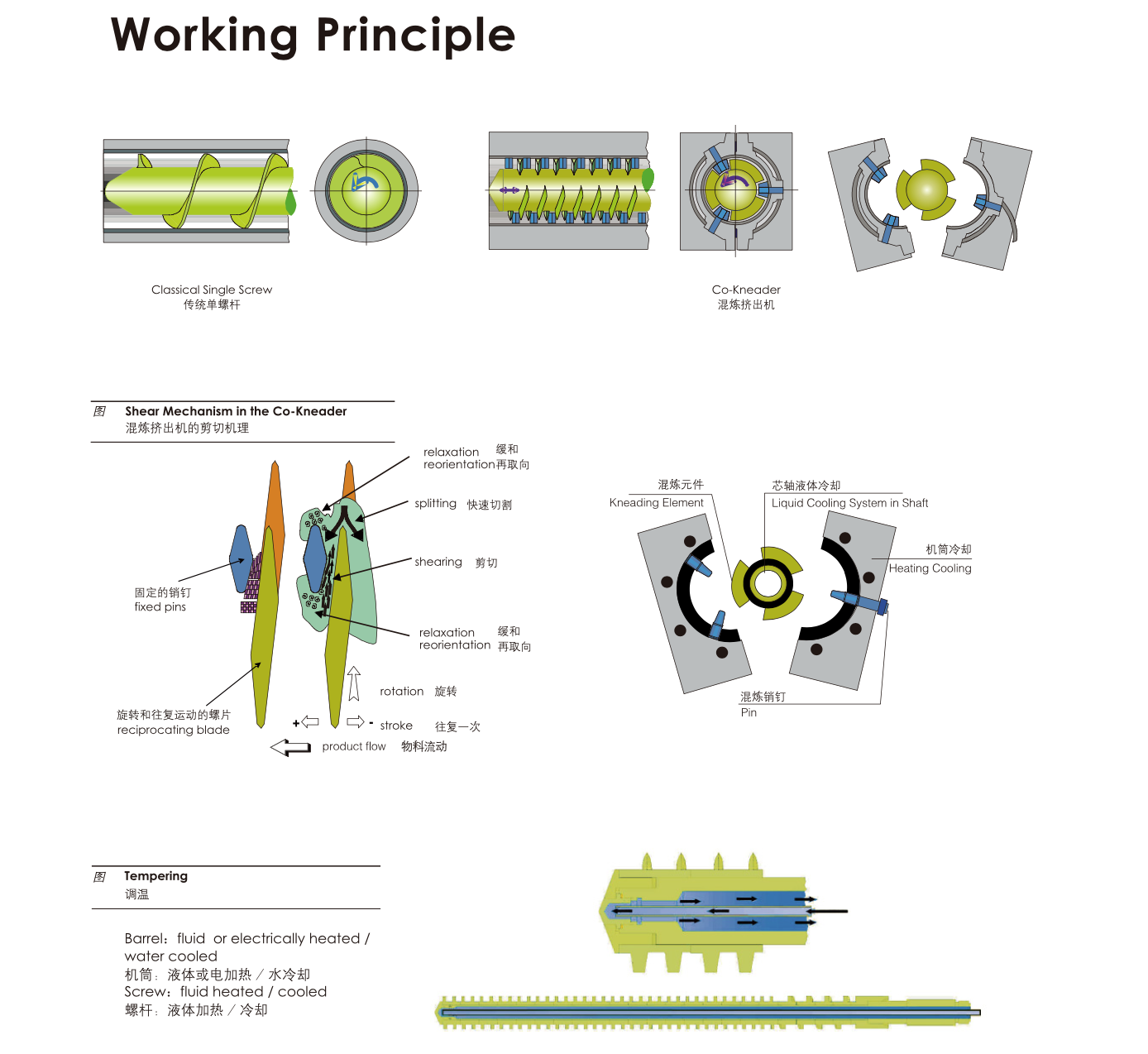

Working Principle

Strength for Co-kneader

Application for Product

Model Reference

(1)SJW(M)--Melt pump is installed between the main extruder and the die. The benefits of melt pumps for extrusion operations includes the elimination of surging and) other fluctuations, reduction of inconsistent melt temperatures, high pressures at lower product temperatures, compensation for the pumping or mixing capacity of the extruder, possibly reduced start-up times, and reduction of energy required by the extruder

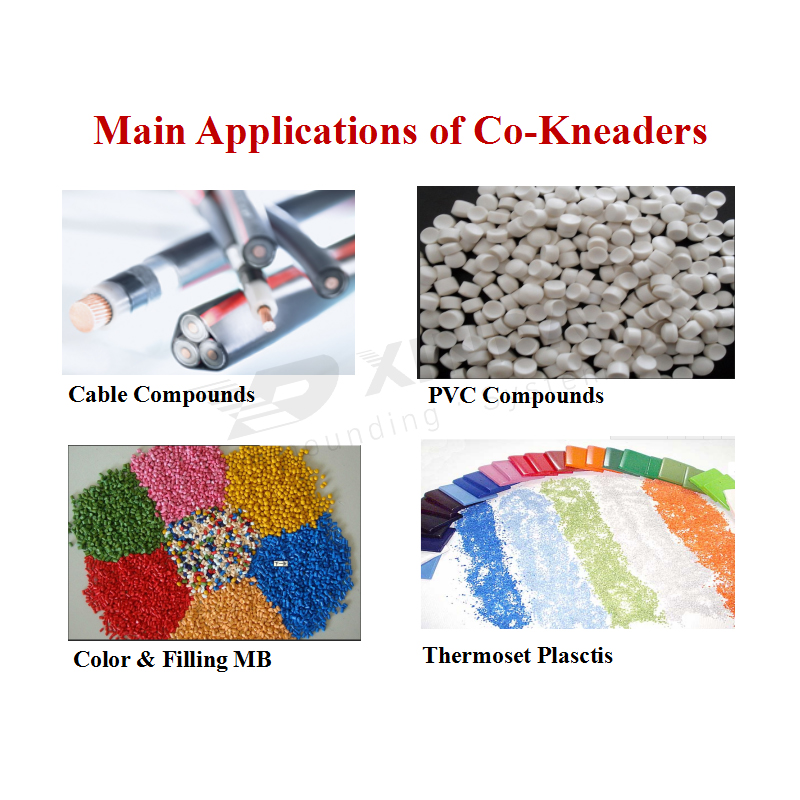

Application:

--Color masterbatch/ Concentrates

--High loading filler masterbatch

--Hot-melt adhesive

--Engineering plastics compounding

--Engineered elastomers

Model SJW-45(M) SJW-70(M) SJW-100(M) SJW-140(M) Screw Diameter (MM) 45 70 100 140 Length Diameter Ratio 15-25 15-25 15-25 15-25 Main Motor Power (KW) 15-30 55-75 90-132 160-220 Max. Screw Speed (RPM) 500 500 500 500 Reference Output (KG/HOUR) 40-50 150-200 300-400 800-1000

(2)SJW(C)--The cascade type of Co-Kneader compounding line is consisted of Co-Kneader main machine and another large size Single Screw Extruder. The stock will fall into the second stage single screw extruder after fully dispersed and distributed in Co-Kneader. It will ensure the materials are processed at lower temperature with the stable extruding The whole process is divided into two parts. Co-Kneader is in charge of kneading while the second stage single screw is focusing on extruding The cascade system is very helpful to achieve the better final quality.

Application:

--PVC compounding pelletizing

--Shoe sole compounds

--Wire cable compounds (XLPE, HFFR, Semi-conductive compounds, etc)

--Concentrated color masterbatch

--Rubber, Final-batch rubber, Master batch, Mixed compound

--Elastomers

--Bio-degradable compounds

--Metal injection molding

| Model | SJW-45(C) | SJW-70(C) | SJW-100(C) | SJW-140(C) | SJW-200(C) |

| Screw Diameter (MM) | 45 | 70 | 100 | 140 | 200 |

| Length Diameter Ratio | 20~25 | 20~25 | 20~25 | 20~25 | 20~25 |

| Main Motor Power (KW) | 15~30 | 55~75 | 90~132 | 160~300 | 350~550 |

| Second-stageScrew Diameter (MM) | 60 | 120 | 150 | 200 | 280 |

| Second-stage L/D | 7~8 | 7~8 | 7~8 | 7~8 | 7~8 |

| Second-stage Power (KW) | 15~22 | 37~45 | 55~75 | 90~110 | 132~160 |

| Max.Screw Speed (RPM) | 500 | 500 | 500 | 500 | 500 |

| Reference Output (KG/HOUR) | 40~70 | 150~250 | 300~500 | 800~1200 | 1900~3600 |

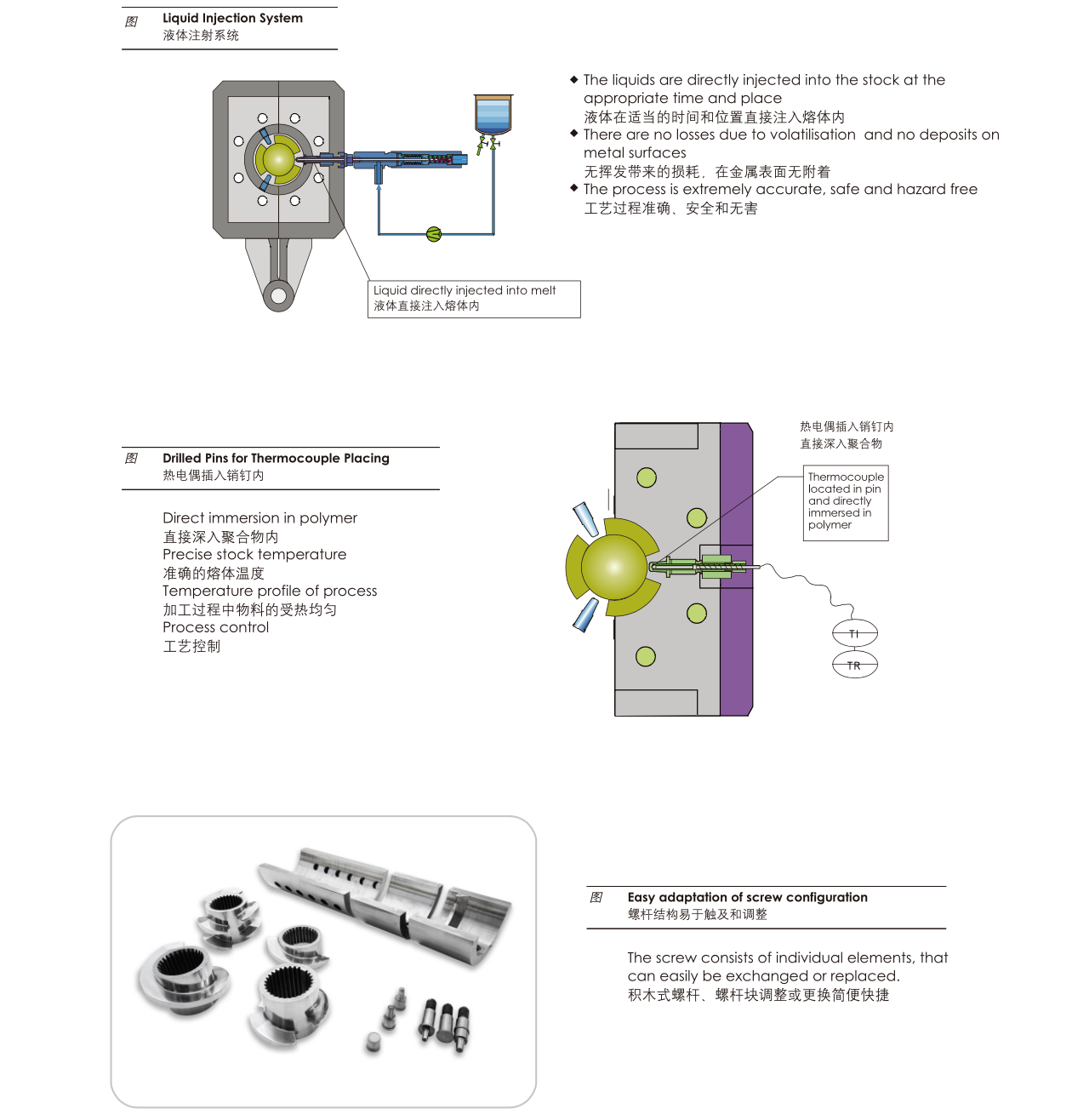

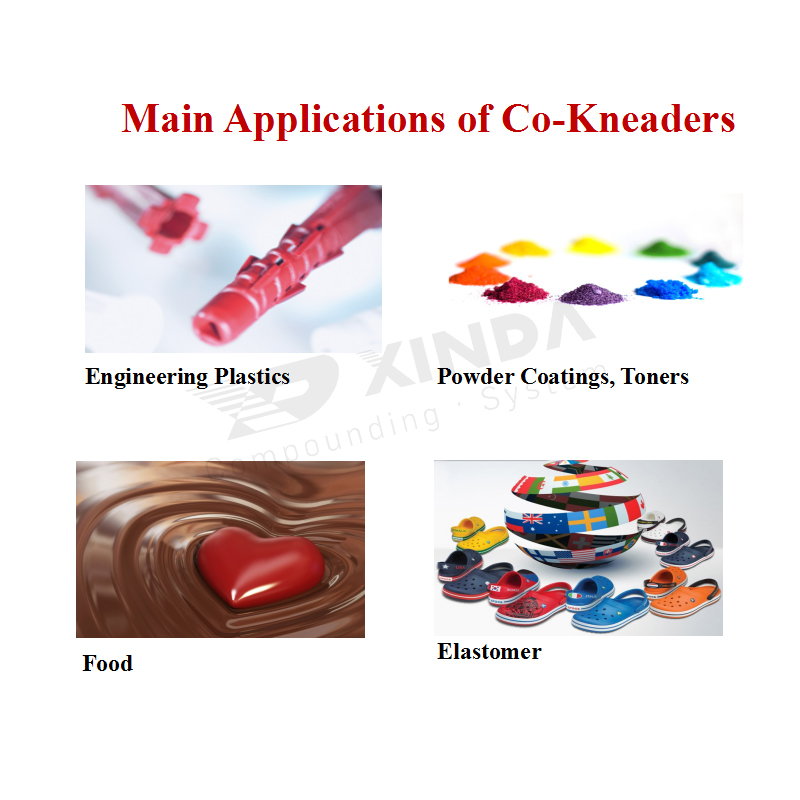

(3)SJW(T)--With the special working principle and shorter L/D ratio of XINDA Co-Kneader enjoys wide application in the field of thermoset plastics compounds and powder coating. Thermocouples can be mounted in drilled kneading pins at various different points along the process section to get the direct contact with the melt. The combination of a liquid heating and cooling system and an extremely precise monitoring of the melt

temperature makes Co-Kneader a very successful solution in thermoset plastics compounds and powder coating toner.

Pvc Compounding Line

Application:

--Thermoset plastics

--Powder coating and toner

--Bakelite molding compounds

--Polymer: epoxy, acrylic, urethane, polyster, etc

| Model | SJW-45(T) | SJW-70(T) | SJW-100(T) | SJW-140(T) | SJW-200(T) |

| Screw Diameter (MM) | 45 | 70 | 100 | 140 | 200 |

| Length Diameter Ratio | 7-15 | 7-15 | 7-15 | 7-15 | 7-15 |

| Main Motor Power (KW) | 15-30 | 55-75 | 90-132 | 160-220 | 350-450 |

| Max. Screw Speed (RPM) | 500 | 500 | 500 | 500 | 500 |

| Reference Output (KG/HOUR) | 40-100 | 100-400 | 300-600 | 500-1000 | 1000-2000 |

Product Description

About factory

Certification

Customers list

Exhibition and Worldwidely

Product Categories : Co-kneader > SJW Serial Co-kneader

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.